Description

NG-1000CCD FA

Standards

Description

All of the benefits of the NG-1000CCD SEMI with the automated Z axis control. Your NG-1000CCD FA can automatically control your focus for complete automation in hardness Vickers and Knoop testing!

NG1000 CCD FA Series – Fully Automatic Micro Vickers and Knoop Hardness Tester

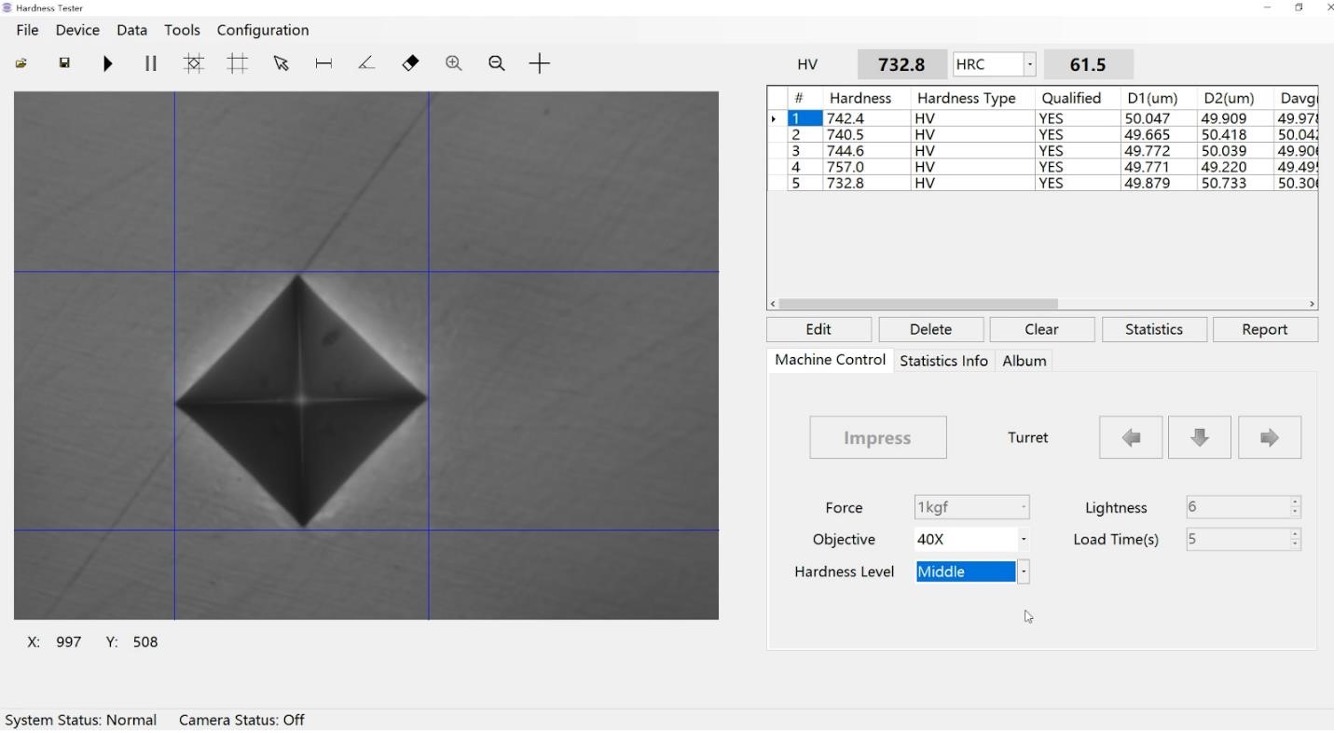

The NG-1000 – Micro Vickers and Knoop Hardness testers are equipped with a large LCD display and a user friendly interface for controlling all aspects of your test. It features a built in printer to allow the operator to print and document the series of hardness readings. The motorized turret automatically controls the changing of the objective lenses and indenter positions for the quickest analysis. The loading and unloading of the test force is fully automated as well and is held for the specified dwell time (1-99 seconds).Our most advanced NG-1000CCD – Micro Vickers and Knoop Hardness tester system includes a high quality CCD Camera and is packaged with our VickSoft Vickers Hardness Test Software. The software will use the indentation image from the CCD camera to detect your Vickers hardness value. Our user friendly VickSoft software allows you to categorize your hardness results by part number/IDs and can then be further exported into a testing report.

Any NG-1000 model can be upgraded to a Semi- or even a Fully-Automatic Hardness Testing System. The Fully-Automatic system has an XYZ stage. This allows the fully automatic system to offer an automatic focus feature. Therefore, after you position the samples and plot the path the unit will perform automatic test and measurement process of indentation, auto-focusing, measuring, and hardness curve plotting with a click of a button.

Software Features: Compatible with NG-1000-CCD Only

Main Functions:

- Auto hardness measurement: With a single click of a button, the software automatically measures the diagonals of the indentation, calculates the hardness value and the statistics (also support manual measurement);

- Hardness curve: With the depths of test points by user input, the software automatically plots the hardness curve(s).User may save and load the depths in a depth template file for later testing for convenience;

- Hardness Conversion: Converts HV to other hardness scales (HRA, HRB, HRC, HBW, HK, and others).

- Data memory / Store function: All data in the process of measurement will be saved in the right bottom sheet.

- Statistics: Automatically updates the statistical values such as average, min and max, standard deviation.

- Test report: Automatically generates WORD report with customizable template;

- Data archiving: Measurement data and images can be saved in one file for later retrieval;

- Knoop Scale: Can be configured for Knoop Scale measurement.

- Other Functions: Includes the basic functions of imaging system such as image capture, camera calibration, image processing, etc.

- Inbuilt camera design, the Software can do indentation image Measure and analysis work; THVS-A software can control Machine turret and adjust lightness.

Main Application Purpose:

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

- Glass, chip and ceramic material.

Standard Configuration:

| Item | QTY |

| Weights Shaft | 1 |

| X-Y Cross Clamping Testing Table | 1 |

| Gradienter | 1 |

| Micro Vickers Hardness Block | 2 |

| Dust-proof Cover | 1 |

| Power Cable | 1 |

| Software | 1 Set |

| Manual | 1 |

| Weights | 6 |

| Level adjustment screw | 4 |

| Objective 10X, 40X | 1 of Each |

| Eyepiece 10X | 1 |

| Screw Driver | 2 |

| Fuse (2A) | 2 |

| Camera | 1 |

| Product Certificate | 1 |

Spare Parts and Consumables:

| Part # | Description of Part # | |

| NG-VKI | Dual Indenter Motorized Turret for Knoop and Vickers Testing Upgrade | |

| The addition of a 4th position on the motorized turret for a Knoop indenter. This allows the user to test either Vickers or Knoop without having to change any indenters. | ||

| NG-VDI | NIST Certified Vickers Diamond Indenter according to ISO 17025 | |

| NG-KI | NIST Certified Knoop Indenter according to ISO 17025 | |

| NG-860 | NIST Certified Micro-Vickers Test Block according to ISO 17025 | |

| Certified and NIST traceable. All loads and ranges available. | ||

| NG-860 | NIST Certified Knoop Test Block according to ISO 17025 | |

| Certified and NIST traceable. All loads and ranges available. | ||

| NG-XY-MICRO | XY Stage with Digital Micrometer Upgrade | |

| NG-FLS2000 | Universal Leveling Fixture for Sample to Help Meet Parallelism Requirements for Hardness Testing | |

| NGFixture1000 | Full Set of Fixtures for your NG-1000DGEN ModelIncludes:

• Flat clamping test table • Thin specimen test table • Filament clamping test table |

|

| NG-AutoSoft | Automatic Software (to be purchased with NG-1000CCD) – Software automatically measures indentation | |

| NG-USB-

1000DGEN |

Upgrade your NG-1000DGEN model to a USB Interface instead of built-inprinter

USB interface instead allows to store hundreds of results. The data will be saved in the U-flash in Excell format. This way you can save thousands of readings without the need for printer. |

|

| NG-2kgf | Add 2kgf Load to your NG-1000 Series Vickers Hardness Tester | |

- Guided by optical cross rails to ensure the highest guiding accuracy

- Fast and smooth force transmission can be achieved by using the secondary transmission force of the rack and pinion.

- This machine is equipped with our most advanced high transmission ratio high precision worm gear rod which can achieve stable continuous lifting, and greatly improved the accuracy and repeatedly of the testing process. This update is in the improved working performance and working efficiency.

- Equipped with dual optical path, one optical path for eyepiece system, another path for CCD camera, both paths can work at the same time without the need to switch the optical path rod. This greatly extend the service life of the optical system, and make the testing process much simpler.

- High definition 8’’ touch screen interface with menu structure and digital eyepiece with a built-in encoder. One-push encoder button provides the diagonal length of indentation D1, D2 and hardness value will display on touch screen directly for easiest and most optimal operation.

- With hardness conversion function, the system can easily convert HV to HRA, HRB, HRC, HBW, and other scales.

- Standard with (HV & HK) Vickers and Knoop hardness testing capabilities.

- OK/NG judgement

- Includes (10X & 40X) lenses for measurement suitable to test wide hardness range of materials from the softest to the hardest of materials.